Last March 30, 2016, I joined a field trip and tour inside a Coca Cola plant in Sta Rosa, Laguna, its one of my dream field trip ever, because I hear so many good stories from my friends that they went here for a school field trip during their elementary and high school days, they are so lucky and it totally suck that our school didn’t brought us here. But Im still thankful that I was selected for a media tour around their plant and get to know more about the journey of a Coca Cola bottle in the Philippines.

The tour is about their two plants in Laguna – the Sta Rosa plant and the Canlubang plant, both of the two plants are the biggest producer of Coca Cola in a bottle in the world, which give service to the entire region of Luzon and nearby islands.

I learned that the Sta Rosa plant is for the processing of returnable and un-returnable glass bottles, while the Canlubang plant is for the processing of PET bottles. They are different from each other, but their purpose is still the same – bring happiness to all Filipinos.

The Coca Cola plant in Sta Rosa, Laguna is very iconic because of their large scale display of Coca Cola cans outside their plant. The view is a main landmark to let you know that you are now in Sta Rosa, Laguna toll gate area. Many people thought that inside these large scale cans are filled with Coca Cola fluids, but I learned from the tour that the giant cans are filled with treated water that comes from the plant.

We arrived inside the Coca Cola FEMSA plant in Sta Rosa, Laguna, we stayed inside a super cooled conference room and we listened to the talk about Coca Cola FEMSA and also followed by some briefing about safety while inside the plant.

so here’s what I learned.

- FEMSA is a company that owns Coca Cola, and they also own Heineken

- FEMSA is present in 10 countries, it started from Latin America and then landed here in the Philippines

- Our Coca Cola Philippine plant in Sta Rosa, Laguna produces 81,000 bottles in an hour, it is considered as the fastest bottling in the world

- FEMSA produces the most iconic beverage in the world -- thats Coca Cola!

- A Coca Cola is made up of 80% water, then sweeteners, sweetness and love from its maker and employees.

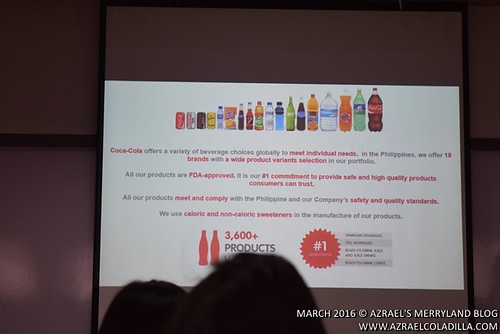

- All ingredients used are safe and made from high quality standards and approved by the FDA.

- The plant follow world class manufacturing standards, they have their own waste segregation, waste water treatment, water resourc management and energy conservation.

- In the Philippines, they have 19 manufacturing plants, 60 sales distribution centers, 10,000 employees, 100,000 family members, 1,015 delivery partners, serving 800,000 sari sari stores and carinderia and 24,000 retail outlets.

- Coca Cola FEMSA PH helps people make a living by just selling the products

- Secret formula of Coca Cola ----- LOVE!

- The Coca Cola Sta Rosa plant process returnable and un-returnable glass bottles. The plant started in 1990 as a glass bottle producer, then on 1997, they started processing the returnable and un-returnable bottles.

- In 2010, the last product to produce are juices and Powerade!

- Coca Cola Sta Rosa asset is 4.3B PHP

- As of now, their Coca Cola Museum is under renovation, it will be opened soon in the mid 2016 and then public tour and field trip will be offered once more.

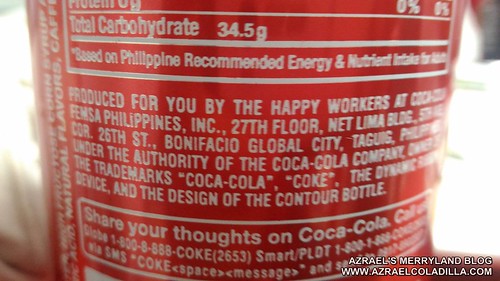

After the briefing, I asked a question on where we can contact Coca Cola if ever we want to complain about the Coca Cola products we bought. They told me that we can contact them through this number 1-800-8-888-COKE (2653) for GLOBE and 1-800-1-888-COKE (2653) for PLDT/SMART.

These phone numbers are printed at the back of a Coca Cola can and also at the label of a Coca Cola PET Bottle.

To my fellow netizens, if may reklamo, itawag mo! wag idaan sa social media kasi di ka nila mapapansin dun. Ok ?

More info about Coca Cola in the Philippines

- 237 ML coca Cola aka TimeOut Coke was launched with a price of PHP7 per bottle, has helped a lot of their sales

- Another product that sells better is the Coke Mismo, a small bottle that you can bring it anywhere because of its small size.

- Sparkle is a typical soft drink brand with lemon flavor, now having a specific growth in the PH market

- 80 percent of their consumers are mid size consumers, that's why Coca Cola changed its product portfolio to reach the lower consumers that can buy lower priced Coca Cola products.

- Coke Life or green Coke with Stevia has no plans yet to launch in the PH

- But more new products to be launched soon

- Coca Cola uses local sugar and its 100 percent from the PH

- In a series of commercial and ads like the "Taste the feeling" campaign, shows that the main actor of the ad is Coca Cola and not people, the campaign is all about the taste and the feeling.

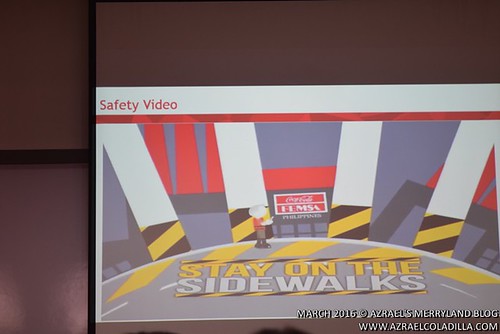

After the information overload…. its so fun to learn about Coca Cola and their operation in the Philippines and how they are helpful in raising a community and family around the plant, next is that we watched a video informercial about the do’s and don’ts while inside the plant. We should follow these rules for safety and also know what to do in case of trouble or emergency.

Im really excited for my first ever field trip inside a Coca Cola Plant.

Are you guys ready for a photo walkthrough?

sayang lang. wala ako video coverage, maybe in my next visit, I can do a video about of this trip.

TOUR STARTS HERE

Entering the Coca Cola Plant in Sta Rosa, Laguna

Lots of signage about safety and also we wore those vest with green reflectors

Busy blogger – Enzo of www.juanmanilaexpress.com

I wasn’t prepared to shoot some videos. Sayang!

We are now at the vicinity of the busiest area of the plant.

And ohhh the sign says it all

There’s the forklift transporting the empty glass bottles to the processing plant

These bottles will be processed by the plant to see which ones can be used again and which ones are needed to be recycled

Bawal dumaan. Kasi there are lots of forklifts crossing in this area.

The processing plant is big!!!

and the weirdest part here is that… its cold

They installed an airconditioner even if the area is not closed

My view from the visitors walkway. Lots of cases of bottles of Coke and Sprite being transported by a conveyor belt going to the processing chamber with computer scanners.

The computer scanners are the ones who can determine if the bottle is damaged or need to be cleaned properly.

At this area, we saw that these Sprite bottles filled with newly Sprite beverage are ready to be transported at the casing station.

All bottles are sealed with a plastic cap

I looked at it and they are so clean and no signs yet of weathering damage. Because the processing plant removed away the not good looking bottles.

At this sealed area…with no humans involved

The bottles are brought to a scanning area.

A proof that all bottles are scanned with the high tech scanner and a computer to check for damages and scanning for unwanted objects or small critters inside.

So it shows that bottles are being scanned for many times to make sure that it is clean and empty.

At this area – no humans involved. The bottles are being scanned again and fired up by strong light or lasers ( I think) for disinfection.

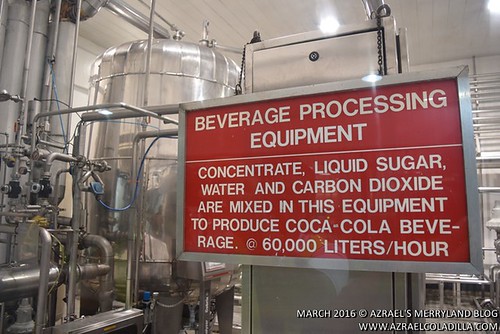

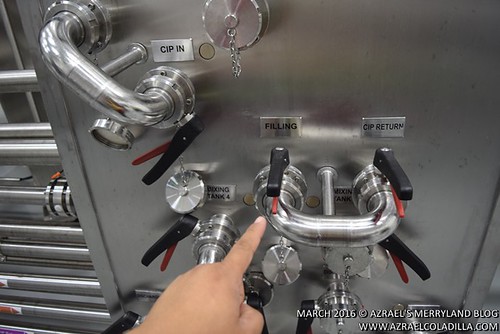

Saw this large tanks filled with Coca Cola beverages.

Nearby are the sealed laboratory area, they do the test here for their formula consistency.

At the far end of the processing plant, I see human workers on stand by to arrange the incoming bottles filled with beverages (sympre all bottles are sealed already )

That’s another round of quality control check.

A series of Sprite bottles are now ready to be delivered to all stores in Manila and Laguna

Sayang, it was a Sprite schedule on that day, a week before daw is a Coca Cola bottle processing.

Forklifts are busy again because newly processed bottles are ready to be transferred in a truck

My last view of the processing plant in Sta Rosa, Laguna

left: empty bottles

right: newly processed bottles ready to be delivered

Meet Ms. Oyee, I met her in our field trip and we learned that she works at Coca Cola for 26 years. She's happy with her job, and she told me that her two kids now finished college and one of them is an upcoming scientist.

At the end of the tour in Sta Rosa, they let us grab a can of Coca Cola from a ref inside the conference center, they told us that the cans are freshly made from the plant.

Im so happy to taste it…perfectly chilled. Coke in cans are always the best.

Also we talked about if there’s a special amount of fizz for each Coca Cola bottles, I told them that the best ever Coca Cola in a bottle is the 1.5 ML, because it generates a good fizz or carbon dioxide when you open it. I heard that PET bottles has more fizz than the ones in a glass bottles? Why? because carbon dioxide escapes easily when in PET plastic bottle vs. glass and cans.

Ohh there’s that weird colored Royal and Scheweppe, another brand that they produced.

tama ba spelling ko? no googling.

Sympre, obligatory photo op with the a Coca Cola bottle statue inside their office.

2nd TOUR

We went to the newly built Coca Cola Canlubang Plant, its just a few minutes drive from Sta Rosa, Laguna. I heard of this plant because it was on the news when our President Aquino visited the site and was there during its inauguration.

For me it’s the biggest plant ever….and also the noisiest plant because of its high tech machines that are so busy producing the Coca Cola in PET bottles.

I started to get confused because of the noise of the machines, I can’t hear a word from my colleagues, but Im glad that they have ear plugs available for us to wear and protect our ears from the noise.

There’s a short briefing before entering this 2nd plant. And ohh I spotted this super cute ref filled with Coca Cola products.

Gusto ko sya iuwi sa bahay! hahaha

We are told to wear these shoes and vest

The factory shoes are custom made for their workers and visitors.

Astig ohhh.. May brand logo ng Coca Cola.

I was about to ask if pwede ko sya iuwi, kaso nahiya ako haha

The shoes are new and so comfy in my feet.

And ohhhh..we are required to wear hair nets ahahah

mukha kami nag salon.

We walked through the plant, its so noisy…and here I spotted some small PET bottles with red sealed cap.

Waste management area..ok move along.

We listened to some of the info about their 2nd plant. Im glad that the sealed room has sound proofing.

The tank filled with Coca Cola formula!!!

Sympre I will take a selfie! haha

Fill it up scotty!

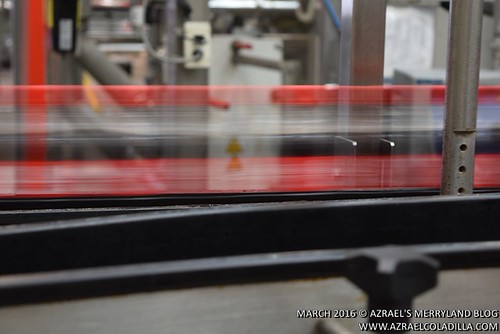

This side of the machine process at high speed --- lots of Coca Cola in small PET bottles are being tested and labeled.

My camera shutter is having a hard time capturing the fast speed of the bottles.

Labeling machine at work

Close up look of the labels

New Coca Cola in small PET bottles are newly labeled. They come out of the machine in a split of seconds.

This small PET plastic thingie are being heated by the machine and then blew it to form your PET bottle.

Its so small and it expands when processed in the machine.

These “tsupon” like thing is made here in the Philippines by another plant by Coca Cola PH.

Looking around..saw some workers managing the label machines

My getaway ladder just in case I need to drink a Coca Cola ahhaha

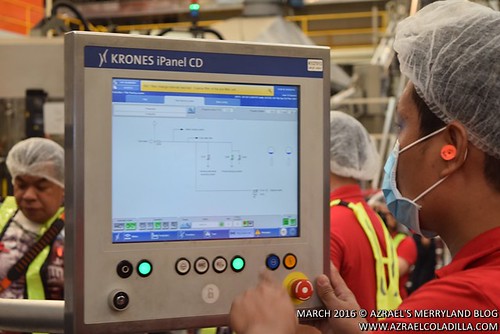

The control panel screen that controls the machines

Here we watched the bottles being filled with Coca Cola

New made bottles filled with Coca Cola beverage and processed with label and red cap are ready to be transported

This machine makes sure that the red caps are well sealed.

Spotted, another sealed laboratory for testing their Coca Cola formula (which is filled with LOVE )

Like in a fashion show runaway…we watched the parade of Coca Cola bottles on a conveyor belt

We’re so tired and its so tempting to grab one.. hhahaa.

pero di pa malamig e

See you at the other side!

Malamang sa tindahan ni Aling Nena

Sometimes machines are disturbed when bottles moved in the wrong way. Here’s one brave worker stopped the machine and grabbed the other bottles who caused the processing cycle. Im glad that they encountered this problem at the packaging machine only.

All Coca Cola bottles are still sealed, all well and clean.

Before we leave the plant…here’s a factoy selfie…

Im so proud that Im here!

Ted of www.wazzup.ph

Enzo of www.juanmanilaexpress.com

That button tempts me to stop the conveyor..ahhaha.

Ok Imma grab a Coke later (outside the plant)

At the other side of the plant, we saw a big warehouse filled with crates of Coca Cola. Here’s a forklift on stand by to transport all crates to a nearby delivery truck

Massive crates of Coca Cola filled the warehouse

Thumbs up!!!!

Well sealed….. no insect or dragon can enter the crate

Take a peak….

Ready for delivery!

There goes the delivery truck…. Tons of bottles will be carried and transported to your suking tindahan

Outside the plant is another warehouse filled with Coca Cola in glass bottles.

These are the bottles needed to be deployed to stores in Laguna

Another round for delivery….

Ready to be consumed….. ahhh sarap nito sa malamig

Sealing it again….before loading it in a truck

Kung malamig ka lang….ubos ka!

Okay, Im so late about these “look under the crown” promo

Load it in…Johnny!

3rd TOUR

So we saw the journey of the bottle….from Processing, filling and bottling.

Now we can see here where they are delivered. Coca Cola showed to us on how they supported local vendors and carinderia operators. Stores are near the plant and they are being Coca Cola-fied, means all products sold here are from Coca Cola PH.

Spotted this sign at the carinderia store of Aling Fely.

Aling Fely’s carinderia best seller are bopis, bulalo and papaitan

Sayang! ubos na yung food. We will visit them next time para matikman ang popular na papaitan ni Aling Fely.

Its cute that every thing bears the colors and iconic shapes of Coca Cola.

According to Aling Fely, all of these are provided for FREE by Coca Cola PH.

March na….may parol pa din haha

A look of Aling Fely’s carinderia

Here we saw another cooling ref at Aling Fely’s carinderia, she told us that Coca Cola provided this for their business. She said that she started from a small eatery and then her business grew bigger after serving and partnering with Coca Cola for years. Now she operates this big carinderia, serving people from the factory in Canlubang, Laguna and passing tourist from Manila.

Sarap talaga mag re-fresh

Me with Aling Fely.

The Coca Cola bottle ends here….and once consumed, the empty bottles will be picked up by the truck and it will be transported back to the processing plant in Sta Rosa, Laguna.

Same process is expected until the bottle reached its unusable state.

4th TOUR

The end of tour is back at the Canlubang Plant office, we stayed in a small carinderia like aircon room and here we listened to a short recap of our tour about the journey of the bottle.

We ate our lunch there and also they served this iced cold Coca Cola with Vanilla ice cream and chocolate syrup.

OMG!! ang sarap! panalo talaga.

At the end of our tour…back in Manila.. Me, Ted and Enzo stayed for awhile in café with Sara of People Asia magazine, we chat about our experience of the Coca Cola Plant Tour and then our discussion went til the end credits of Batman V Superman movie.

Awesome day

and Awesome experience with Coca Cola.

Gusto mo ba sumama sa next Coca Cola plant tour?